Sub Categories

Filtering

-

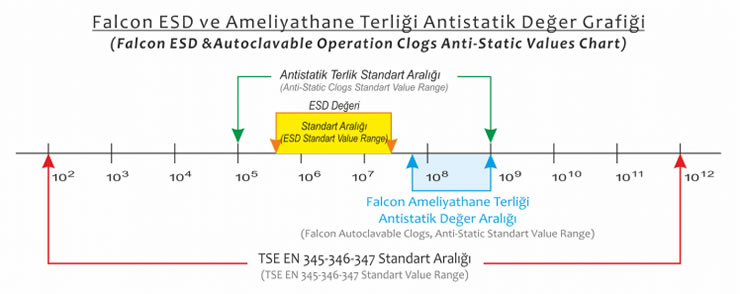

Antistatic Properties: The slippers are designed with antistatic properties to prevent the buildup and discharge of static electricity. This feature is crucial in sensitive environments like electronic factories, where static discharge could damage sensitive equipment.

-

ESD Protection: Antistatic operating room OT clogs provide Electrostatic Discharge (ESD) protection for workers in electronic manufacturing facilities. They prevent static electricity from damaging electronic components and help maintain a safe working environment.

-

Non-Slip Soles: The slippers come with non-slip soles to provide secure footing on various surfaces, reducing the risk of slips, trips, and falls in critical areas like operating rooms or clean rooms.

-

Hygienic Design: These slippers are designed with hygiene in mind, featuring washable and autoclavable materials that can be easily cleaned and sterilized to maintain a clean environment in healthcare settings.

-

Antimicrobial Properties: Some antistatic slippers may also include antimicrobial properties to inhibit the growth of bacteria and fungi, reducing the risk of cross-contamination in medical facilities.

-

Comfort and Breathability: The slippers are made with breathable materials and ergonomic designs to ensure comfort during extended wear, allowing healthcare professionals and workers to focus on their tasks without discomfort.

-

Compliance with Industry Standards: These slippers are typically manufactured to meet relevant industry standards and safety regulations, ensuring they are suitable for use in sensitive environments.

-

Durable Construction: The slippers are built with durable materials to withstand the demands of daily use in various settings, providing long-lasting performance and value.

-

Versatility: Antistatic operating room slippers are versatile and can be used in a range of environments, including healthcare centers, clean rooms, pharmaceutical companies, laboratories, and veterinary clinics.

-

User Safety: By reducing the risk of static discharge and providing a secure grip, these slippers enhance user safety, protecting both workers and the equipment they handle.

-

Hospitals: In hospitals, where infection control and hygiene are of utmost importance, antistatic operating room OT shoes with washable and autoclavable features help maintain a clean environment. Their non-slip soles ensure safe movement in busy and potentially hazardous areas.

-

Clean Rooms: Clean rooms demand strict cleanliness and static control to protect sensitive equipment and maintain product integrity. Antistatic cleanroom shoes prevent static discharge, ensuring that workers do not damage electronic components or disrupt critical processes.

-

Pharmaceutical Companies: Pharmaceutical manufacturing requires controlled environments to avoid contamination. Antistatic slippers models contribute to the cleanliness and prevent static interference during production and handling of sensitive medications.

-

Laboratories: In laboratories, accuracy and precision are vital. Antistatic slippers protect delicate instruments from electrostatic discharge and help maintain a controlled environment for accurate testing and research.

-

Veterinary Clinics: Similar to hospitals, veterinary clinics benefit from the hygienic and non-slip properties of antistatic slippers. These slippers ensure the safety of veterinary staff while handling animals and reduce the risk of cross-contamination.

-

Antistatic Properties: The primary and most significant difference is the inclusion of antistatic properties in the operating room slippers. Regular slippers typically do not possess this feature, which is essential in sensitive environments like operating rooms, clean rooms, and electronic factories. Antistatic properties prevent the buildup and discharge of static electricity, protecting both workers and sensitive equipment from potential damage.

-

ESD Protection: Antistatic operation theatre slippers provide Electrostatic Discharge (ESD) protection, making them suitable for workers in electronic manufacturing and handling environments. ESD can harm electronic components and disrupt critical processes, making antistatic slippers a crucial safety measure.

-

Hygiene and Sterilization: Operating room slippers are designed with hygiene in mind. They are often made from washable and autoclavable materials, allowing for easy cleaning and sterilization to maintain a clean and sterile environment in healthcare and pharmaceutical settings. Regular slippers may not have such considerations.

-

Non-Slip Soles: Antistatic operating room theatre clogs come with non-slip soles to provide secure footing on various surfaces, reducing the risk of slips and falls. This feature is crucial in areas where spills or wet floors are common, such as operating rooms and laboratories.

-

Antimicrobial Properties: Some antistatic operating room slippers may include antimicrobial properties to inhibit the growth of bacteria and fungi, contributing to infection control efforts in medical facilities. Regular slippers may not have such properties.

-

Compliance with Safety Standards: Operating room slippers are manufactured to meet industry safety standards and regulations, ensuring their suitability for use in critical environments. Regular slippers may not undergo such rigorous testing and certification.

-

Durable Construction: Antistatic operating room slippers are built with durable materials to withstand the demands of daily use in medical and industrial settings. They are designed for long-lasting performance and reliability.

-

Application-Specific Design: Operating room slippers are purposefully designed for the unique needs of healthcare professionals, clean room workers, and technicians. They provide support, comfort, and protection in environments where precision and safety are paramount.

- 119.00 USD

- 119.00 USD

- 119.00 USD

-

Safety and Stability: Surgeons perform intricate and delicate procedures that require precision and stability. Proper surgical footwear, such as Hospital OT shoes, provides a secure and slip-resistant grip on the operating room floor, reducing the risk of slips, trips, and falls during critical procedures.

-

Infection Control: Operating rooms require a high level of cleanliness and sterility to prevent infections. Hospital OT shoes are designed to be washable and autoclavable, making them easy to clean and maintain the required hygiene standards.

-

Antistatic Properties: Hospital OT shoes often come with antistatic properties, which prevent the buildup and discharge of static electricity. This is especially important in operating rooms and other sensitive medical environments where static discharge could damage sensitive equipment.

-

Comfort and Ergonomics: Surgeons spend long hours on their feet during surgeries. Hospital OT shoes are designed for comfort and support, helping to reduce fatigue and discomfort during extended periods of standing and walking.

-

Compliance with Standards: Wearing appropriate footwear, such as Hospital OT shoes, ensures that surgeons comply with hospital policies and safety standards, promoting a safe and professional working environment.

-

Professional Appearance: In addition to safety and functionality, wearing proper surgical footwear reflects a professional image and reinforces the importance of adhering to established protocols and procedures in the operating room.

-

ESD Protection: Antistatic slippers provide Electrostatic Discharge (ESD) protection, preventing the accumulation of static electricity on the wearer and reducing the risk of damaging electronic components or sensitive equipment during handling or assembly.

-

Conductive Materials: Antistatic slippers are made from materials that have conductive properties, allowing static charges to flow safely through the shoes and into the ground, rather than building up on the wearer.

-

Non-Slip Soles: To ensure safety in the workplace, antistatic slippers often have non-slip soles, providing secure footing on various surfaces, especially in areas where spills or wet floors are common.

-

Comfort and Durability: Antistatic slippers are designed for comfort during extended wear and are typically made from durable materials to withstand the demands of industrial environments.

-

Hygiene Considerations: In healthcare settings or clean rooms, antistatic slippers may be designed to be washable and autoclavable, allowing for easy cleaning and sterilization to maintain a clean and sterile environment.

What are the key features of your antistatic operating room OT Clogs, and how do they enhance safety in sensitive environments?

Are these slippers suitable for use in hospitals, clean rooms, pharmaceutical companies, laboratories, and veterinary clinics?

Yes, antistatic operating room OT theatre footwear are indeed suitable for use in hospitals, clean rooms, pharmaceutical companies, laboratories, and veterinary clinics. These slippers are specifically designed to meet the unique requirements of sensitive environments, providing safety, hygiene, and comfort to healthcare professionals, workers, and visitors. Here's how these slippers can be beneficial in each setting:

In each of these settings, antistatic operating room slippers provide a practical solution to mitigate risks associated with static electricity and ensure a safer and more efficient working environment. Their versatility makes them a valuable addition to industries and workplaces that prioritize safety, cleanliness, and precision. When choosing antistatic slippers, it's crucial to ensure that they comply with relevant industry standards and meet the specific needs of the intended environment.

What makes these operating room OT Clogs different from regular slippers or footwear commonly used in medical settings?

Antistatic operating room OT clogs are distinct from regular slippers or footwear commonly used in medical settings due to several key features and design considerations. Here are the main factors that set them apart:

Are the OT Clogs washable and autoclavable?

It can be autoclaved for 3 minutes at 121 degrees 15 minutes and 134 degrees flash sterilization. It can be autoclaved at least 200 times if you follow the autoclave times.

Adequate temperature, pressure and times for autoclave sterilization are 1 atm and 15 minutes at 121°C, total time 40 minutes when the device is operated empty; 2 atm and 3 minutes at 134°C, and 20 minutes when the device is operated empty.

Use with washing bag in washing machine or autoclave with shelf. If the autoclave is produced only for slippers, it can be used without a bag.

Also OT clogs can be washable up to 90 degrees.

Note: Do Not Use Vertical Type Autoclave Machine!

OT Clogs

What are the uses of OT clogs?

* Operating theaters

* Laboratories

* Clean Rooms

* Pharmaceutical companies

* Cleaning staff

* Hotels

* Sterile and Non-sterile areas

* Medical and healthcare companies

* Bakeries

* Factories producing electronic products ( ESD shoes )

O.T Shoes Online

You can buy our OT shoes online from our website

Why is it important to surgeons?

It is essential for surgeons to wear appropriate and specialized footwear for several reasons:

What is Antistatic?

Antistatic refers to a property or characteristic of materials or devices designed to prevent the buildup or discharge of static electricity. Static electricity is a stationary electric charge that can accumulate on the surface of an object when there is friction or contact with another material. It occurs due to the transfer of electrons between surfaces, leading to an unbalanced electrical charge.

In antistatic materials or devices, measures are taken to control or neutralize static electricity to prevent potential damage to sensitive electronic components or equipment and reduce the risk of harm to individuals in certain environments. Antistatic measures are particularly important in industries where static electricity can interfere with electronic circuits, such as in electronic manufacturing, clean rooms, laboratories, and operating rooms.

Antistatic properties can be achieved through various methods, such as incorporating conductive materials, using antistatic coatings, or creating a pathway for static charges to dissipate safely. For example, antistatic flooring, clothing, footwear, and equipment are designed to prevent the accumulation of static charges and ensure a safe working environment in sensitive areas where static discharge could cause damage or disruption.

What are antistatic slippers?

Antistatic slippers are a type of footwear designed with special properties to prevent the buildup and discharge of static electricity. They are used in environments where static electricity poses a risk to sensitive electronic equipment or processes. Antistatic slippers are particularly common in industries such as electronics manufacturing, clean rooms, laboratories, and operating rooms.

The main features of antistatic slippers include:

Antistatic slippers play a crucial role in mitigating the risk of static discharge in sensitive environments and ensuring the safety of both workers and valuable electronic equipment. They are an essential component of ESD protection strategies in industries where static electricity could lead to costly damage or compromise product quality.